PPC ČAB has been electrifying the world for long 65 years

Only a few companies can boast of their long activity for 65 years.

PPC Čab has the honor to celebrate this anniversary in 2020, and on that occasion not only to celebrate but also to balance, express gratitude, and set new goals.

PPC Čab started production in 1955 as the first company in Slovakia dedicated to the manufacturing of electrical porcelain and technical porcelain. Since then, porcelain electrical insulators have helped secure the transmission of electricity in more than 100 countries around the world, where they have been exported over the years.

The first name of the company was „Prvá slovenská porcelánka“, but it was changed several times, as the owners of the company were changing. In 1960, the company became one of the seven plants of the „Elektroporcelán Louny“, as the No. 05 „Čab plant“, and the name of village Čab became synonymous with the products produced in this factory.

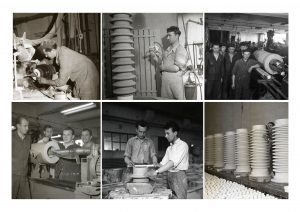

Historical photos from the 60s of the 20th century

Historical photos from the 60s of the 20th century

In 1991, the company became a subsidiary of the CERAM INSULATORS holding company. In 2001 with an acquisition of Riverside / PPC Insulators the „PPC ČAB“ started to be used as a name of the company. In 1993, one of the first companies was successfully certified according to ISO 9002 and in 1994 according to ISO 14001.

PPC Čab has been a member of the Seves Group since 2007, and in recent years the company underwent visible changes and significant improvements.

Primary production has grown from manual turning and casting into molds to isostatic pressing, dry and plastic turning on CNC machines. The isostatic manufacturing process provides the ability to produce larger insulators with a manufacturing time reduction to 2-3 weeks from 8-10 weeks, in comparison with the traditional plastic method. A tunnel kiln replaced the „circle“ kiln, and in 2018 the Grün kiln was put into operation. Grün has significantly lower gas consumption compared to Bickley and tunnel kiln used in the past. It also helps to increase the production capacity.

Kiln Grün

Kiln Grün

The product portfolio consists of hundreds of types of porcelain electrical insulators for applications up to 1200 kV AC and 1100 kV DC. Over the years, the plant´s production capacity grew to 6,5 t of fired porcelain per year. The increase was significantly supported by the transfer of technology and production equipment from a sister plant in Austria realized in 2017-2018. Hand in hand with it came the renovation of production and shipping halls, hiring new employees, and overall modernization.

Turning of an insulator

Turning of an insulator

Currently, 180 people work at PPC Čab and the company presents an important medium-sized employer in the Nitra region. The loyalty of employees is proving that the company really cares for its people. Often, a few members of families work here, and some of them all their life long. In recent years, the company has been organizing meetings with former colleagues, and some of them worked there at the very beginning of production. A lot of people have still a strong connection with their „mother’s“ company. „Porcelánka“ raised generations of families who know how important it´s to ensure the safe distribution and transformation of electricity.

We are really proud that our insulators were supplied to almost all continents. PPC ČAB is focusing on the operation of its plant with the greatest possible respect to the environment and economic efficiency. In 2001, the „Lean Six Sigma“ program was implemented with high investments in education. The main points of this program were projects leading to waste reduction. In the last two years, lighting in productions halls was changed to LED, it was introduced more economical heating in halls, and also the packaging of our products was changed to a more eco-friendly form. Our area was decorated with new greenery and paintings on the walls.

New LED lights in the manufacturing halls

New LED lights in the manufacturing halls

New decoration of buildings in the PPC ČAB area

New decoration of buildings in the PPC ČAB area

New canteen of PPC ČAB

New canteen of PPC ČAB

Just recently, a new canteen has been put into operation. It will not only increase work comfort, but it is contributing to the strengthening of interpersonal relationships. Our responsibility to society, the planet, and our employees will be supported by further investments.

We would like to thank all current and former employees for their contribution to the fact that we can proudly say that the „Prvá slovenská porcelánka“, today´s PPC Čab, a member of the PPC Insulators group, is a modern and prosperous company whose products are bringing the light around the world for 65 years.